Shuang Bang has been producing waterproof and breathable PU membrane for decades. We successfully develop PU membranes for different applications. To customize the products easier, develop new product faster, and provide more competitive price to our customers, we use the PU resins we manufacture.

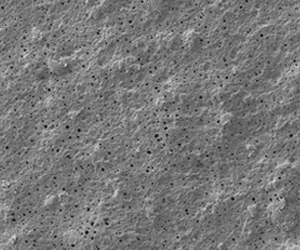

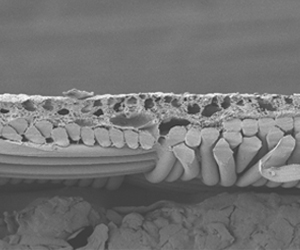

The first wet process PU coating production line was added since 2009, and later started to product micro-porous PU products. By directly coating the functional PU resins on fabric, then dipping into water tank, then high concentration of DMF will permeate into low concentration water. With the exchange process between DMF and water, PU resin gradually forms microporous structure on the substrate. This process makes the products have good waterproof and moisture permeable performance. In general, the touch of microporous PU film is smoother and richer than others.

| Product Name | Width (inch) |

Water Sportswear |

Outdoor Clothing/ Sportswear |

Camping Equipment |

|---|---|---|---|---|

| Hydrophilic moisture permeable waterproof treatment | 58" | V | V | V |

| Hydrophobic moisture permeable waterproof treatment | 58" | V | V | V |

Transfer Lamination

In transfer lamination process, functional agents and color pigments are added to customize functional products. The performance of transfer lamination product can achieve waterproof (JIS L1092B): 20,000/ M.V.P (JIS L1099B1): 20,000.

| Product Name | Width (inch) |

Water Sportswear |

Outdoor Clothing/ Sportswear |

Camping Equipment |

Work Clothing |

Medical Supplies |

Shoes Material |

|---|---|---|---|---|---|---|---|

| Hydrophilic moisture permeable waterproof treatment |

60”~85” | V | V | V | V | ||

| Hydrophobic moisture permeable waterproof treatment |

60”~85” | V | V | V | V | V | |

| Waterproof treatment | 60”~85” | V | V | V | |||

| Color gel treatment | 60”~85” | V | V | V | V | V | V |

| Anti-Bacterial and Anti-fungus treatment |

60”~85” | V | V | V | V | ||

| High frequency treatment | 60”~85” | V | V | V | V | V | |

| Light shielding and flame retard treatment |

60”~85” | V | V | V |

Dot Lamination

Dot lamination process provides customer flexible options. Various combination, excellent hand feel, solvent free and light weight are the advantages of dot lamination. Nowadays, more and more customers choose dot lamination process for these advantages.

| Product Name | Width (inch) |

Water Sportswear |

Outdoor Clothing/ Sportswear |

|---|---|---|---|

| Fabric to fabric | 58 | V | V |

| Fabric to PU/TPU membrane | 58 | V | V |

| 3-layer lamination | 58 | V | V |

Using Shuang Bang’s own PU resin as the main material, and with high technology inputs into PU membrane, which brings out waterproof and breathable properties to achieve the best results, and thus enhance the value added to textiles. In response to the diverse needs of the market, Shuang Bang develops different types of PU membranes for different kinds of fabric and function.

| Product Name | Width | Thickness | Water Proof | M.V.P. | ||

|---|---|---|---|---|---|---|

| (inch) | (mm) | Test Method | mm-H2O | Test Method | g/m2/24hr | |

| Flexible Membrane | 60 | 0.02-0.04 | JIS L1092B | 10,000 | JIS L1099 A1 | 3,000 |

| Microporous Membrane | 58 | 0.07-0.09 | JIS L1092B | 10,000 | JIS L1099 A1 | 8,000 |

| Hydrophobic Composite Membrane | 60 | 0.05-0.06 | JIS L1092B | 10,000 | JIS L1099 A1 | 5,000 |

| Hydrophobic Membrane | 60 | 0.025-0.03 | JIS L1092B | 10,000 | JIS L1099 A1 | 5,000 |

| Hydrophilic Membrane | 60 | 0.02-0.025 | JIS L1092B | 10,000 | JIS L1099 B1 | 50,000 |

| Hydrophilic High WP Membrane | 60 | 0.025-0.03 | JIS L1092B | 20,000 | JIS L1099 B1 | 120,000 |

| Water Proof Color Membrane | 60 | 0.02-0.04 | JIS L1092B | 10,000 | JIS L1099 B1 | 0 |

Application

| Product Name | Water Sportswear |

Yoga Clothing |

Outdoor Clothing/ Sportswear |

Camping Equipment |

Shoes Material |

|---|---|---|---|---|---|

| Flexible Membrane | V | V | V | V | |

| Microporous Membrane | V | V | V | V | |

| Hydrophobic Composite Membrane | V | V | V | V | |

| Hydrophobic Membrane | V | V | V | V | |

| Hydrophilic Membrane | V | V | V | V | |

| Hydrophilic High WP Membrane | V | V | V | V | V |

| Water Proof Color Membrane | V | V | V |