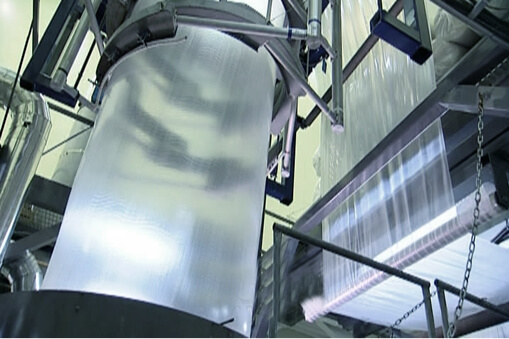

Introducing Tpu Series Of Products In 2008

From the manufacture of TPU pallets to finished TPU film, the consistent production operations not only control the quality, reduce costs, and also be customized with the customers’ needs, and effectively use on end products.

-

Application:

- .Clothes: TPU waterproof breathable film.

- .Shoes: High frequency welding, brand Logo, no sewing vamp.

- .Medical: Medical bedding tube, medical rehabilitation inflatable materials.

- .Outdoors: Outdoor air mattress, water bag.

- .Future development: automobile materials and electronics products.

01Moisture permeability film

TPU Film 0.015-0.15mm

This series of products marked with "*" can pass the certification of GRS or bluesign.

This TPU series perform excellent waterproof ability and moisture permeability. Through its hydrophilic chemical structure, TPU could rapidly vaporize and remove sweat, bringing cozy and comfortable wearing experience.

Product Application: Fabric lamination, windbreaker, raincoat, snowsuit, cold jacket, field jacket, diaper, diving suit, swimming suit, bodysuit, slimming suit.

| Item | Hardness Shore A ASTM D-2240 |

Moisture Vapor Transmission g/m2/24hr L1099 B1 |

Hydrostatic Resistance mm-H2O JIS L 1092 B |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

Melting Point ℃ TMA |

| CM-8157N | 85±3 | >40,000 | >15,000 | >50 | >70 | >100 | >70 | 165~175 |

|---|---|---|---|---|---|---|---|---|

| CM-8207N | 85±3 | >40,000 | >15,000 | >50 | >70 | >100 | >70 | 165~175 |

| WM-8207N | 85±3 | >40,000 | >15,000 | >45 | >65 | >90 | >70 | 165~175 |

| *CB-8207 | 85±3 | >40,000 | >15,000 | >50 | >70 | >100 | >70 | 168~178 |

| *CR-8207 | 85±3 | >40,000 | >15,000 | >50 | >70 | >100 | >70 | 168~178 |

| *WB-8207 | 85±3 | >40,000 | >15,000 | >45 | >65 | >90 | >70 | 165~175 |

| CM-8205N | 80±3 | >75,000 | >15,000 | >40 | >50 | >75 | >60 | 165~175 |

| WM-8205N | 80±3 | >75,000 | >15,000 | >40 | >50 | >75 | >60 | 165~175 |

02General film

TPU Film 0.015-0.10mm

This TPU series offers excellence in waterproof ability and physical property.

Product Application: Fabric lamination, case, box and bag, air cushion and medical material, windbreaker, raincoat, snowsuit, cold jacket, field jacket, diving suit, swimsuit, bodysuit.

| Item | Hardness Shore A ASTM D-2240 |

Moisture Vapor Transmission g/m2/24hr L1099 B1 |

Hydrostatic Resistance mm-H2O JIS L 1092 B |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

Melting Point ℃ TMA |

| C-1253 | 90±3 | <1000 | >20,000 | >80 | >150 | >300 | >80 | 165~185 |

|---|---|---|---|---|---|---|---|---|

| C-0253 | 85±3 | <1000 | >20,000 | >70 | >200 | >250 | >90 | 155~165 |

| C-0708 | 85±3 | <1000 | >20,000 | >60 | >140 | >200 | >90 | 130~140 |

| C-0606 | 90±3 | <1000 | >20,000 | >70 | >300 | >350 | >80 | 150~170 |

01TPU Extrusion Film

TPU Film 0.145mm-2.0mm

This series of products marked with "*" can pass the certification of GRS or bluesign.

This TPU film series is a transparent thermoplastic polyurethane film/sheet. Clients can customize film surface, there are different emboss or transparency that client can choose. All depends on customer needs. The features of our TPU films are great flexibility, abrasion resist, easy for H/F welding, and good UV stability.

| Item | Hardness Shore A ASTM D-2240 |

Specific Gravity g/cm3 ASTM D-792 |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

UV-resistance Grade ASTM-D1148 |

Melting Point ℃ TMA |

| US-9206 | 95±3 | 1.2±2 | >100 | >150 | >250 | - | >4 | 163~173 |

|---|---|---|---|---|---|---|---|---|

| US-1005 | 86±3 | 1.2±0.05 | >40 | >65 | >250 | - | >4 | 137~147 |

| *UE-6300 | 90±3 | 1.2±0.05 | >71 | >188 | >400 | - | >4 | 173~183 |

| US-3550 2L | 90±3 | 1.2±2 | >85 | >165 | >250 | - | >4 | 160~170 |

| *US-1221 | 85±3 | 1.2±0.05 | >45 | >70 | >300 | - | >4 | 127~150 |

| US-9350 | 85±3 | 1.2±0.05 | >45 | >70 | >300 | - | >4 | 127~137 |

| UE-2140 | 85±3 | 1.2±0.05 | >60 | >114 | >400 | - | >4 | 160~170 |

| US-2180 | 82±3 | 1.2±0.05 | >40 | >50 | >250 | - | >4 | 115~130 |

| US-9550 | 82±3 | 1.2±0.05 | >40 | >60 | >210 | - | >4 | 122~132 |

| US-8070RP | 80±3 | 1.2±2 | >34 | >40 | >49 | - | >4 | 75~85 |

02ecoPure TPU series

Water Base PU/TPU & Water Base PU/TPU/HMA

With the global warming and climate change rising, environment protect is the biggest issue right now. It associates with our daily life. When Shuang-Bang is pursuing for business sustainability also looking for environment coexist to maintain the balance.

In traditional oil based PU, it can be used at a variety of field. With the traditional PU progress it will harm the factory workers and customer health due to the DMF (Dimethylformamide) from inside. Shuang-Bang positively develops water-based PU synthetic leather. The product doesn’t have mineral metal, plasticizer, DMF (Dimethylformamide) inside. Also the manufacture progress doesn’t have solvent remains until finish, customers and factory worker can safely use.

TPU muti-layer film is using a transparent thermoplastic polyurethane film/sheet as adhesive. The top layer is water- based PU film. Clients can customize PU pattern, color and transparency on the surface.

Application: shoes and no-sew process garment.

| Item | Hardness Shore A ASTM D-2240 |

Specific Gravity g/cm3 ASTM D-792 |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

UV-resistance Grade ASTM D1148 |

Melting Point ℃ TMA |

| EL-20 | 77±3 | 1.15±0.05 | >30 | >40 | >150 | >40 | >4 | 210~220/120~130 (Skin/TPU) |

|---|

03CHROMA series

Solvent Base PU/TPU & Solvent Base PU/TPU/HMA

TPU muti-layer film is suing a transparent thermoplastic polyurethane film/sheet as adhesive. The top layer is anti-hydrolysis PU film, which the pattern, color and transparency on the surface can be changed according to customer needs.

Application: shoes and no-sew process garment.

| Item | Hardness Shore A ASTM D-2240 |

Specific Gravity g/cm3 ASTM D-792 |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

UV-resistance Grade ASTM D1148 |

熔點 Melting Point ℃ TMA |

| EL-10 | 82±3 | 1.15±0.05 | >30 | >40 | >150 | >40 | >4 | 170~180/120~1 30 (Skin/TPU) |

|---|

04Breathable film series

Breathable PU/HMA

Breathable TPU multi-layer film is using a breathable thermoplastic polyurethane film/sheet as adhesive. Breathable PU is used in the top layer to achieve the best performance of breathable and waterproof. Clients can customize the top layer surface. It has different emboss, color, and transparency.

Application: shoes and no-sew process on garment

| Item | Hardness Shore A ASTM D-2240 |

Moisture Vapor Transmission g/m2/24hr L1099 B1 |

100% Modulus Kg/cm2 ASTM D-412 |

300% Modulus Kg/cm2 ASTM D-412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Tear Strength Kg/cm ASTM D-624 |

UV-resistance Grade ASTM D-1148 |

Melting Point ℃ TMA |

| EL-30 | 67±3 | 7000±3000 | >20 | >30 | >60 | >30 | >4 | 210~220/120~130 (Skin/TPU) |

|---|

01TPU Pellet

This series of products have great hydrolysis resistance, UV resistance. In TUP series is polyether. TUG series is polyester. TUE series is high elastic hot-melt adhesive. TUH series is regular hot-melt adhesive. You can choose suitable TPU materials to fit you manufacture line.

Application: footwear, textile, no sew, fabric, adhesive laminating, sealing tape, etc.

| Item | Hardness Shore A ASTM D-2240 |

100% Modulus Kg/cm3 ASTM D412 |

300% Modulus Kg/cm3 ASTM D412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Elongation % ASTM D412 |

Tear Strength Kg/cm ASTM D-624 |

UV resistance ASTM D1148 |

Melting Point ℃ TMA |

| TUG-85AH8 | 85±3 | 56 | 72 | 250 | 650 | 85 | 4 | 127±5 |

|---|---|---|---|---|---|---|---|---|

| TUG-90AH8BF | 90±3 | 70 | 110 | 300 | 600 | 120 | 4.5 | 165±5 |

| TUG-95AH8 | 95±3 | 165 | 230 | 320 | 450 | 135 | 4 | 165±5 |

| TUP-85AK6 | 85±3 | 65 | 95 | 250 | 700 | 80 | 4.5 | 165±5 |

| TUP-90AK6 | 90±3 | 75 | 110 | 300 | 600 | 120 | 4.5 | 178±5 |

| TUW-85AK6 | 85±3 | 53 | 80 | 200 | 750 | 85 | - | 178±5 |

| TUH-8010U | 77±3 | 34 | 43 | 165 | 650 | 50 | 4.5 | 122±5 |

| TUH-80ABH | 80±3 | 45 | 93 | 300 | 650 | 95 | 4.5 | 118±5 |

| TUE-75AH6 | 70±3 | 22 | 32 | 110 | 1000 | 50 | 4.5 | 120±5 |

| TUE-60AH6 | 60±3 | 15 | 24 | 110 | 1000 | 50 | 4.5 | 130±5 |

| TUH-7022L | 70±3 | 30 | 38 | 100 | 800 | 40 | - | 100±5 |

02low carbonization-TPU Pellet

This series of product is designed for low carbon emission. Using r-PET and bio-based ingredient as the raw materials can greatly decrease carbon emission and environment impact. It can decrease 50% of the carbon footprint by comparing our original TPU product footprint and low carbon emission footprint. The ideal situation is going to decrease 35% footprint, bio-based ingredient content 45%, r-PET content 25%

Application: footwear, textile, no sew, fabric, adhesive laminating, sealing tape, etc.

| Item | Hardness Shore A ASTM D-2240 |

100% Modulus Kg/cm3 ASTM D412 |

300% Modulus Kg/cm3 ASTM D412 |

Tensile Strength Kg/cm2 ASTM D-412 |

Elongation % ASTM D412 |

Tear Strength Kg/cm ASTM D-624 |

UV resistance ASTM D1148 |

Melting Point ℃ TMA |

| TUG-85AP15G | 85±3 | 50 | 60 | 150 | 750 | 60 | 4 | 125±5 |

|---|---|---|---|---|---|---|---|---|

| TUG-85AP16G | 90±3 | 50 | 65 | 180 | 700 | 60 | 4 | 160±5 |

| TUH-8015HG | 75±3 | 30 | 40 | 70 | 500 | 40 | 4 | 95±5 |

| TUG-80AP10G | 85±3 | 48 | 75 | 154 | 700 | 63 | 4 | 165±5 |

| TUG-90AP10G | 90±3 | 70 | 110 | 200 | 550 | 80 | 4 | 185±5 |

| TUE-7021H | 60±3 | 12 | 12 | 25 | 200 | 21 | 4 | 90±5 |

| 8588 pellet | 85±3 | 50 | 65 | 180 | 700 | 55 | 4 | 127±5 |

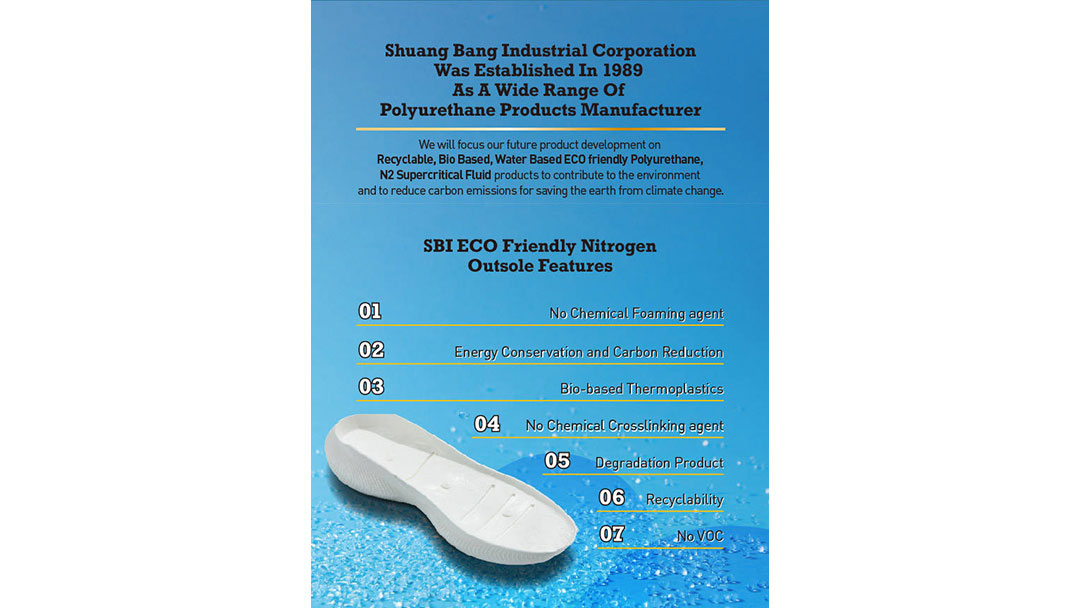

Type:TPU Midsole of nitrogen filling of physical foaming.

Features:Recyclable, good flexible, well UV resistance, GRS approval.

Application:Footwear.

- Much superior resilience and rebound to traditional EVA outsole.

- SBI outsole is lightweight.

- Energy Conservation and Carbon Reduction.

- Recyclability

- Bio-based thermoplastics

- No VOC

- No Chemical Crosslinking agent

- No Chemical Foaming agent

- Zero Chemical Additives are used during physical foaming.

Physical Properties:

| Property | Unit | Standard | FUP-50C | FNU-50C | FUS-50C |

| Type | - | - | Ether | Ether | Bio-ester>40% |

|---|---|---|---|---|---|

| Density | g/cm3 | ASTM D297 | 0.18~0.2 | 0.16~0.18 | 0.18~0.2 |

| Hardness | Shore C | ASTM D2240 | 47~53 | 48~52 | 50~54 |

| Tensile strength (without skin) |

kgf/cm2 | ASTM D412 | 14~16 | 7~9 | 17~19 |

| Elongation (without skin) |

kgf/cm2 | ASTM D412 | 350~400 | 140~190 | 280~350 |

| Tearing test (without skin) |

kgf/cm2 | ASTM D624 | 8~9 | 5~7 | 10~13 |

| Resilience | kgf/cm | ASTM D2632 | 42~46 | 54~60 | 32~36 |

| Compression set | % | CNS3560 K6351 | 8~16 | 8~16 | 40~48 |

| UV grade | grade | ASTM G154 | 4 | 5 | 4 |

| Ross Flex (23°C) | Times | SATRA TM92 | >125,000 | - | - |

| Heat agent(60°C) | grade | JIS K7373 | 4 | - | - |

Storage:

Please store in a cool and dry setting and keep it out with sunlight. The storage life is a year only, please check the quality and durability if it is expired.

Note:

Please inspect the compatibility before any manufacturing process since it may affect physical property, reliability and durability. For more technical issues, please contact Shuang-Bang Industrial.